São Paulo Metro Line 6, Brazil – Tunnelling and Structural Monitoring

The challenge - tunnelling in complex urban conditions

The São Paulo Metro Line 6-Orange is one of the largest underground infrastructure projects in Latin America, extending 15.3 km through densely urbanised neighbourhoods. The alignment passes beneath multi-storey residential blocks, historic structures, operational metro lines, and transport viaducts, all within geologically variable ground conditions.

Traditionally, geotechnical monitoring programmes in metro projects rely on manual instrumentation such as inclinometers, surface settlement markers, and piezometers, which are read periodically by survey teams. While effective in many contexts, manual methods typically produce a limited frequency of readings (often once or twice daily) and require direct site access. In São Paulo, this approach presented three major challenges:

- Restricted access: At locations where tunnelling passed below operational metro lines, the only permitted access was during short night-time closures (01:00–03:00). This restricted measurements to one reading per night, inadequate for detecting rapid changes in displacement or settlement.

- Geological risk: The TBM alignment passed close to fault zones, fractured granite, and a high water table, increasing the likelihood of differential settlement and angular distortion in overlying structures. Manual monitoring alone could not provide the level of temporal resolution needed to verify predicted vs. actual ground behaviour.

- Sensitive structures: Sections of the alignment passed within metres of the foundations of 10-storey buildings and a nearby viaduct. Here, even minor undetected displacements could have compromised structural safety.

These constraints highlighted the need for a continuous, automated system capable of providing high-frequency data and real-time alerts.

The solution - integrated manual and automated remote monitoring

To address these challenges, ACCIONA implemented a hybrid monitoring programme combining manual and automated methods, with a strong emphasis on wireless automated instrumentation supplied by Senceive.

Wireless Tilt and Displacement Sensors

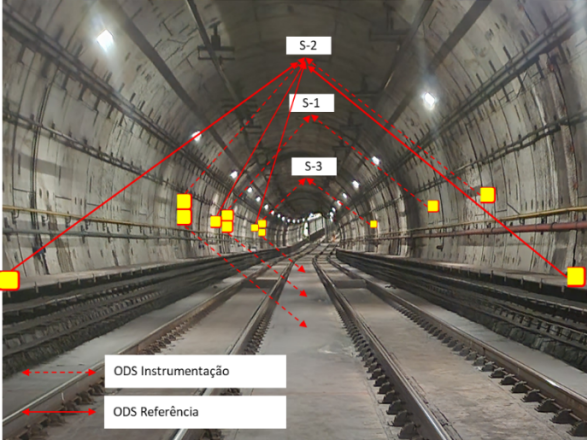

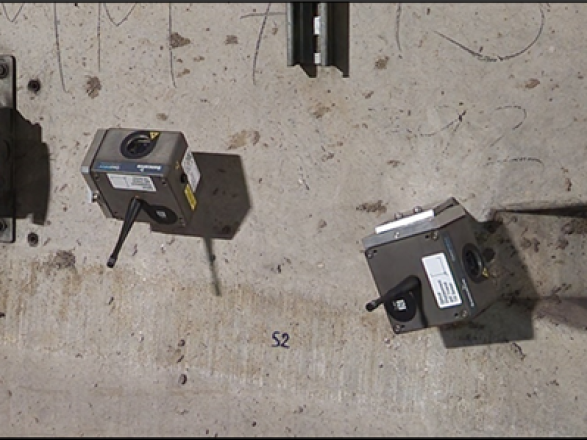

Compact triaxial tilt sensors were installed on representative points of high-rise buildings, tunnel linings, and critical structures. Each sensor measured rotational movement across X, Y, and Z axes, providing a precise assessment of settlement and angular distortion. In addition, Optical Displacement Sensors (ODS) were deployed on rail tracks and tunnel joints to record differential settlement and convergence.

Wireless Communications Architecture

All sensors communicated via Senceive’s wireless mesh/point-to-point network to Gateways. Gateways were positioned to ensure robust communication and were capable of transmitting data either via ethernet/WiFi or more commonly by cellular network. This allowed continuous operation without reliance on site power or extensive cabling infrastructure.

Data Management and Alarming

Measurements were programmed at hourly intervals, generating up to 24 readings per day per sensor. This was a 24-fold increase compared to the single daily manual readings previously planned. Data were transmitted automatically to Senceive’s WebMonitor platform, where they were stored, processed, and visualised. Threshold exceedance levels were configured to trigger automated alerts via SMS and email, ensuring immediate awareness of any significant structural or ground movement.

Deployment Strategy

To optimise cost and coverage, the monitoring programme used a relocation methodology. Two independent systems, each consisting of one Gateway and six Triaxial Tilt Sensors, were rotated across multiple structures as the TBM progressed. This allowed monitoring of 12 selected buildings over a 28-day average instrumentation window (five days of TBM passage plus pre- and post-monitoring for installation and testing).

In total, 32 structures—including residential towers and the viaduct—were monitored along a 4.8 km tunnel section. Additional automated total stations and video monitoring were deployed in parallel on operational metro lines (Lines 1 and 4), enabling continuous surveillance of rail alignment and tunnel convergence.

Monitoring outcome – more comprehensive data to manage construction risk, at lower cost

The integration of automated instrumentation provided measurable technical and operational benefits:

Increased temporal resolution: Sensor nodes delivered one reading per hour (24 daily readings), compared to one manual reading per day. This enabled identification of short-term patterns and early detection of displacement trends that would otherwise have been missed.

Correlation with manual measurements: Comparative studies between manual convergence readings and wireless tilt/ODS data in adjacent tunnels demonstrated a high degree of correlation, validating the accuracy of the automated system.

Cost efficiency: Despite the higher unit cost of automated sensors, the ability to relocate systems as the TBM advanced produced an overall 66% cost saving relative to a fully manual approach, while still providing far greater data density.

Risk mitigation: Continuous monitoring ensured that tunnelling below sensitive structures—including the Quatorze Bis viaduct, where TBM clearance was less than one metre from foundations—was completed without recorded movements exceeding threshold parameters.

Operational integration: On Lines 1 and 4, where access constraints precluded effective manual monitoring, the automated system enabled continuous, remote observation. This ensured excavation adjacent to operational metro tunnels could proceed without disruption to passenger services.

Sustainability gains: Reductions in manual site visits lowered annual travel by 17,520 km and reduced CO₂ emissions by over 1,000 litres of fuel equivalent. In parallel, the automated groundwater monitoring (CCR) system introduced elsewhere on Line 6 reduced unnecessary water extraction by 71%, protecting local aquifers.

By 2024, the monitoring programme had incorporated 279 automated sensors, delivering an additional 5.5 million readings on top of the 10 million manual readings taken across the project. This represented a 55% increase in total dataset size, significantly enhancing the resolution and reliability of geotechnical monitoring.

In summary, the São Paulo Metro Line 6-Orange project demonstrates the value of automated wireless instrumentation in urban tunnelling environments.

Senceive’s tilt and displacement sensors provided continuous, reliable data under challenging conditions, enabling ACCIONA to safeguard critical infrastructure, manage geotechnical risk, and optimise monitoring resources—achieving both safety and cost efficiency without exceeding the original budget.

Downloads

Created on: Wed 21st Jan 2026