Click the products to learn more.

Vibrating Wire Sensor Node with Piezometer

The Vibrating Wire Sensor Node supports a variety of interface sensors such as crack, strain gauges and extensometers. Here it is connected to a piezometer and prevents the need for manual logging by transmitting data on pore water pressure and groundwater level variations.

Get more information

InfraGuardTM

Wireless tilt sensors are mounted on stakes. The sensors detect rotational movements and send scheduled data reports. Sudden movement events are also detected as they happen, regardless of the pre-set sampling schedule.

When thresholds are breached, sampling is accelerated, and nearby nodes are triggered to accelerate reporting.

When a camera is integrated into the system, photographs are taken on a scheduled basis and when triggered by sudden movement.

Get more information

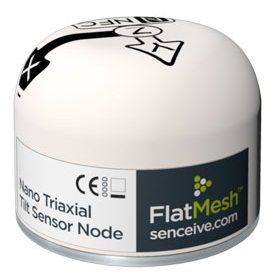

NanoMacro Triaxial Tilt Sensor Nodes

Wireless tilt sensors installed on trackbed can measure rail track heave/differential settlement, cant and twist. With no external antenna and a durable shell, the Nano is ideal for the most challenging environments.

Get more information

Millivolt Sensor Node

The Millivolt Sensor Node enables a variety of structural and geotechnical sensors to be integrated into a wireless monitoring system. Strain gauges on trackbed are just one example. A node cap helps protect the antenna from passing track workers.

Get more information

PT100 RTD Sensor Node

The PT100 RTD Sensor Node enables precise temperature monitoring and critical rail temperature alerting. Can be supplied with an integrated High-G triaxial tilt sensor for combined tilt and temperature monitoring.

Get more information

FlatMesh 4G Gateway

The FlatMesh 4G Gateway provides all the functionality required to operate a wireless sensor network in a remote location. With a solar panel, no fixed power supply is required. Data is transmitted from the sensors to the Gateway and onwards to a secure cloud-based server and data management platform.

Get more information

FlatMesh CameraHub

Solar-powered Camera with built-in EdgeHub. Clear, high-quality images day or night. Used as an integral part of InfraGuard monitoring solution. The camera can be set to take photos at regular intervals, on demand or most interestingly, when triggered by movements detected in nearby sensors.

Get more information

FlexiMeasure

FlexiMeasure is a lightweight Inclinometer that can be installed in any orientation; segments can be connected to form a chain of flexibly coupled triaxial sensors. Here it can be seen measuring/monitoring changes in the profile of the tunnel wall.

Get more information

Optical Displacement Sensor Node (ODS)

The ODS combines a tilt meter and a laser displacement sensor. Together they provide information about the stability of the structure the sensor is fixed to and relative movement of a target structure.

Here it is measuring convergence of the tunnel intrados.

Get more information

Crack Sensor Node

The Crack Sensor Node is used to monitor structural movement including crack movement, expansion joint movement and pile separation. Here it is monitoring the movement of a crack on the tunnel headwall.

Get more information

Digital Interface Node

The Digital Interface Node is a wireless digital data logger that enables automated sampling. It is compatible with many types of sensor that carry a digital output. Interact and manage your data online and change reporting times and thresholds remotely.

The Digital Interface Node is compatible with InfraGuardTM. Choose this responsive reporting option when you need dynamic reporting. This means your sensors can be self-managing tools that react to changing site conditions. Features include accelerated sampling, triggered site photos and escalated alerting, with near real-time notifications.

Get more information